Polypropylene Fibres TREVON

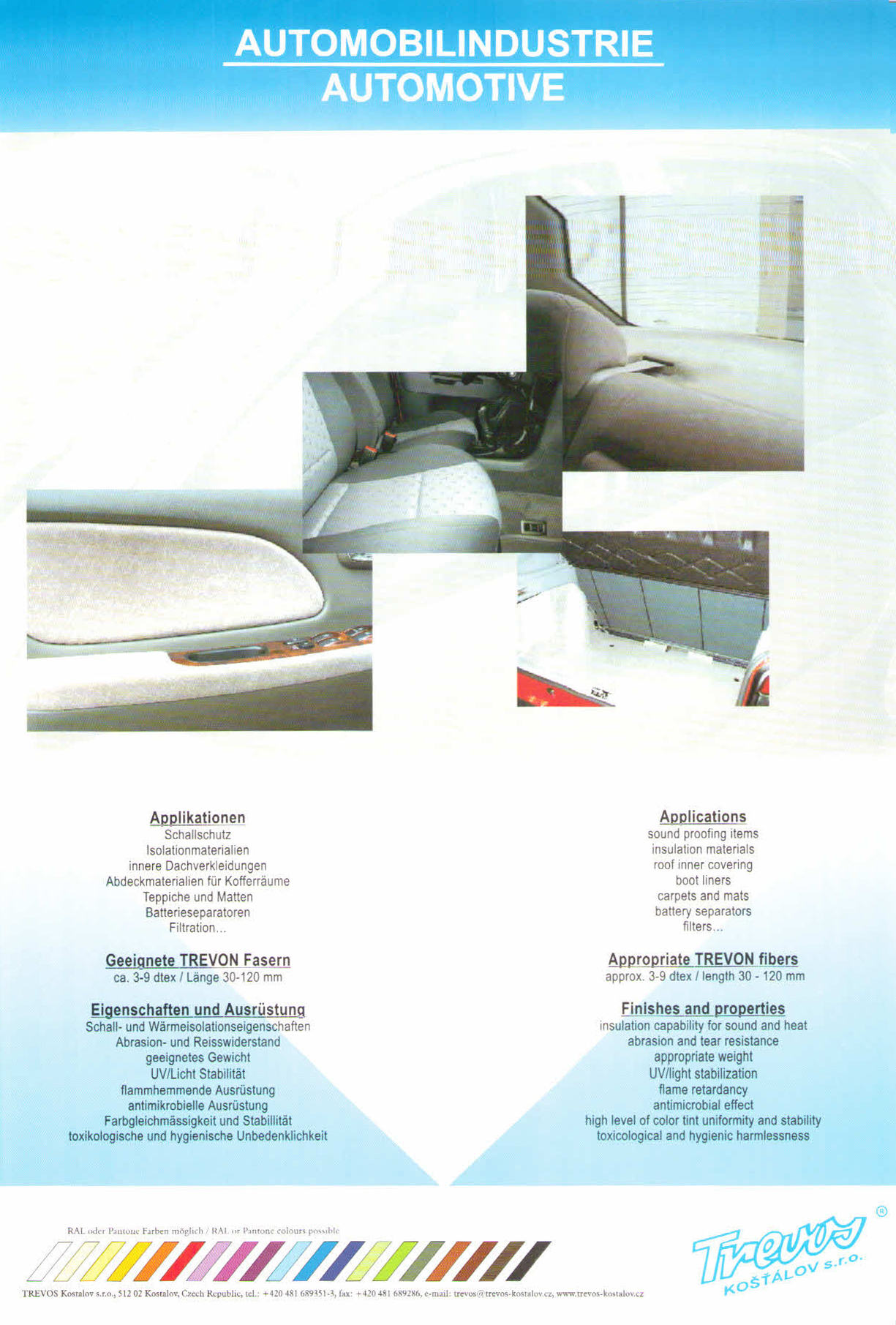

AUTOMOTIVE INDUSTRY

Applications

- sound proofing items

- insulation materials

- wadding components

- roof inner covering

- rear parcel shelves

- boot liners

- carpets and mats

- battery separators

- filters

For the above mentioned applicatiosn can polypropylene fibers be used both as substrate and surface material. This combination of identical types is comparatively easy to process and can serve as the raw material for new substrates. In this way, the recycling circle is closed, and the requirement for waste reduction in the disposal of old cars can be met.

Appropriate TREVON fibers

Titer approx. 3 - 11 dtex

Cut length 30, 40, 50, 60, 75, 90, 120 mm

* letter V stands for tenacity above 40 cN/tex and W for tenacity over 45 cN/tex (see Figure )

Finishes and properties

For applications in this area the TREVON fibers have to fulfill streng quality requirements to be able to bear the demanding conditions in the car interiors and have to offer:

- insulation capability for sound and heat

- abrasion and tear resistance

- appropriate weight

- UV/light stabilization

- flame retardancy

- high level of color tint uniformity and stability

- very low levels of fogging

- toxicological and hygienic harmlessness

- smooth and clean surface

- shock absorbing capacity

- good processability in different processes (carding, thermobonding, needlepunching...)